Services

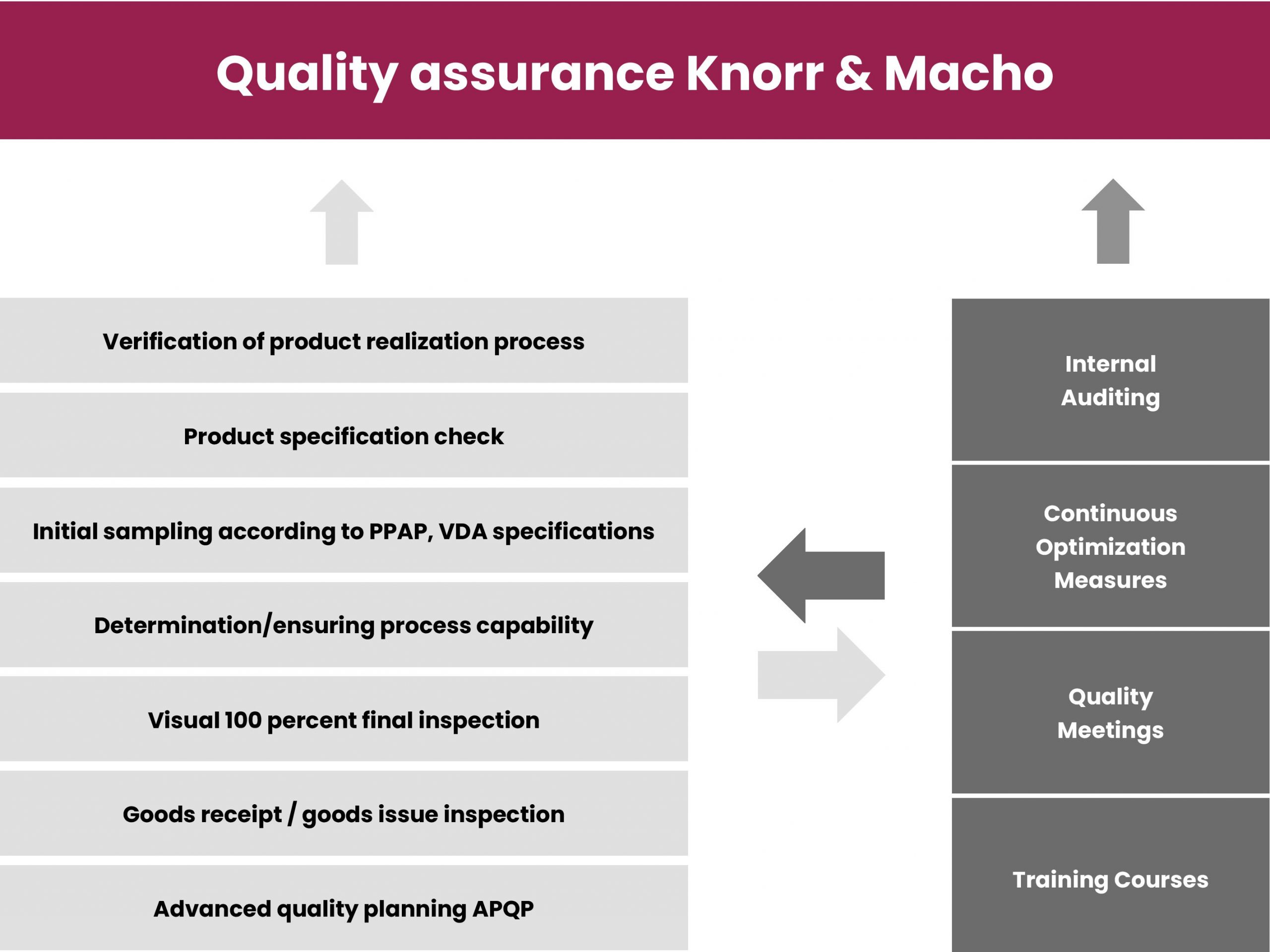

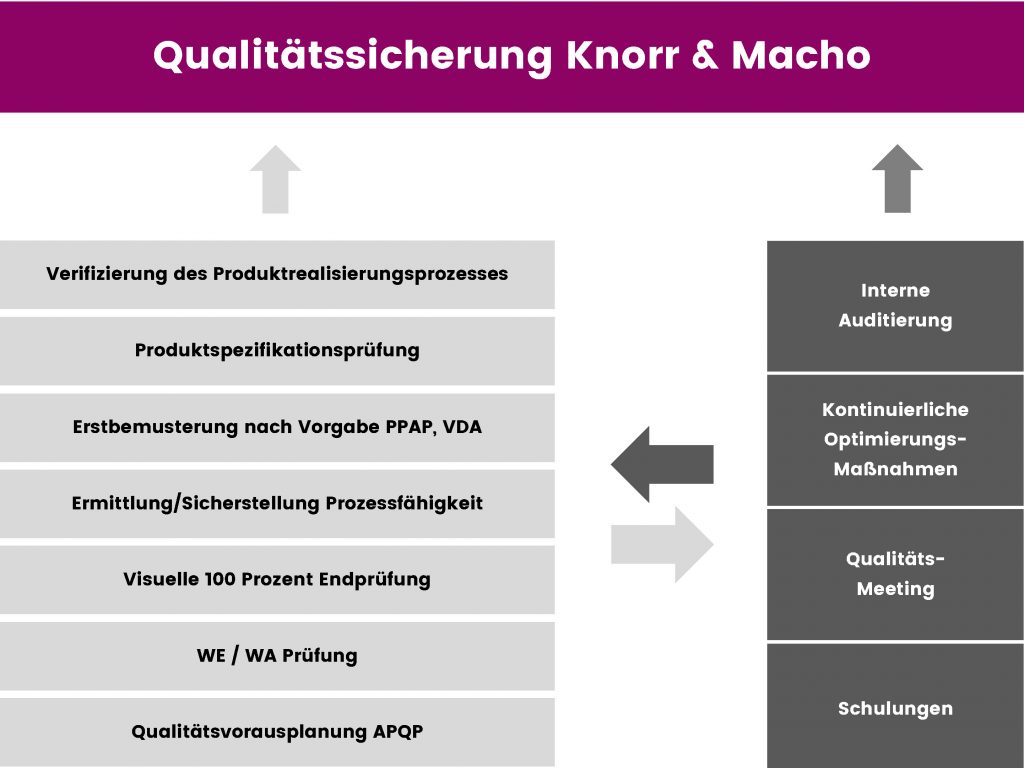

Quality assurance.

Your contact person

Herr Andre Wagner

Head of quality and environmental

First-Class molded rubber parts

Quality as daily standard.

Nowadays quality is an absolute matter of course and due to the many specifications, process structures and documentation requirements, requires sustainable development in order to meet the many requirements.

That is why we guarantee the best possible quality for our customers as part of a continuous improvement process (CIP), regular audits and optimization measures.

According to DIN EN ISO 9001

This claim is defined in regular quality meetings, or important processes and procedures as well as current issues are discussed and appropriate measures are defined if necessary. The basis is our certified quality management according to DIN EN ISO 9001:2015, which is integrated in all company areas/processes.

Qualification measures

Our qualified employees are also regularly trained on customer and product-specific requirements and undergo appropriate qualification measures at regular intervals.

According to DIN EN ISO 9001

This claim is defined in regular quality meetings, or important processes and procedures as well as current issues are discussed and appropriate measures are defined if necessary. The basis is our certified quality management according to DIN EN ISO 9001:2015, which is integrated in all company areas/processes.

Qualification measures

Our qualified employees are also regularly trained on customer and product-specific requirements and undergo appropriate qualification measures at regular intervals.

Process-Related Tests

As part of series production, shift-accompanying quantitative and qualitative SPC product tests are also carried out and since 2016 have been documented and evaluated by using CAQ software and then forwarded to the responsible persons. After final processing, our molded rubber parts undergo a 100 percent visual final inspection by our certified and experienced service providers and are subjected to an outgoing goods verification before delivery.

Previous

Next

Automated InspectionSince the end of 2013, Knorr & Macho GmbH has undergone a fully automated, visual 100 percent final inspection of the corresponding molded rubber parts (preferably round parts). The inspection process, which views the molded rubber part from above and below as well as from the side (360° all-round inspection) using high-resolution high-speed cameras, not only includes a visual final inspection of all surfaces for example cracks, old material, holes, residual grade, etc., but also checking the specified dimensional tolerances for the inside and outside diameter, ovalization, residual degree, etc.

Depending on the nature and shape of the molded rubber part, it is individually adjusted to its standard-specific specifications and possible fault characteristics as part of the testing system, the parameters are then saved and the testing process is evaluated.

Automated Inspection

Since the end of 2013, Knorr & Macho GmbH has undergone a fully automated, visual 100 percent final inspection of the corresponding molded rubber parts (preferably round parts). The inspection process, which views the molded rubber part from above and below as well as from the side (360° all-round inspection) using high-resolution high-speed cameras, not only includes a visual final inspection of all surfaces for example cracks, old material, holes, residual grade, etc., but also checking the specified dimensional tolerances for the inside and outside diameter, ovalization, residual degree, etc.

Depending on the nature and shape of the molded rubber part, it is individually adjusted to its standard-specific specifications and possible fault characteristics as part of the testing system, the parameters are then saved and the testing process is evaluated.

Previous

Next