Companie

Production.

Your contact person

Mr. Dieter Weber

Production management

RUBBER MOLDING PRODUCTION

Flexibility and precision in TOP quality.

Based on this basic understanding, we have been manufacturing a wide variety of technical molded rubber parts for an international customer segment for over 30 years. Priority for the automotive industry.

The basis is our high-modern and extensive machine park, which currently consists of 23 different injection molding machines with a pressing weight from 160 to 460 tons.

As part of our "Injection Moulding" production process using cold runner technology or hot runners, all of our molded rubber parts go through a production process that operates at the highest level. Whether small series or millions of pieces, for example rubber bellows, rubber seals, rubber membranes, rubber grommets and plugs, precision and small parts, damping elements or connecting elements play no role.

We guarantee the quality awareness of our production through a shift-accompanying and article-specific SPC-guided production control via CAQ system at specified time intervals. Another important quality factor in our production is the human resource component. After the actual injection process has been completed, the demolding process requires technical skill, responsibility and commitment. All of our production employees / machine operators life these characteristics every day and implement them through successive training courses.

Furthermore we work together with long-standing large-scale mixture suppliers who produce 95 percent in Germany and have been able to rely 100 percent on their experience, know-how and delivery reliability (even in times of Corona) for many years.

Machine

Tons

Tool

Tool

Manufacturing process

Depending on the geometry, number of calibers and the resulting of tool design, we produce on the Basis of the injection molding by "hot runner or cold runner technology". We offer an optimal, effective and efficient implementation of the molded parts in TOP quality, for example, rubber seals, bellows, rubber grommets, precision and micro parts, and much more.

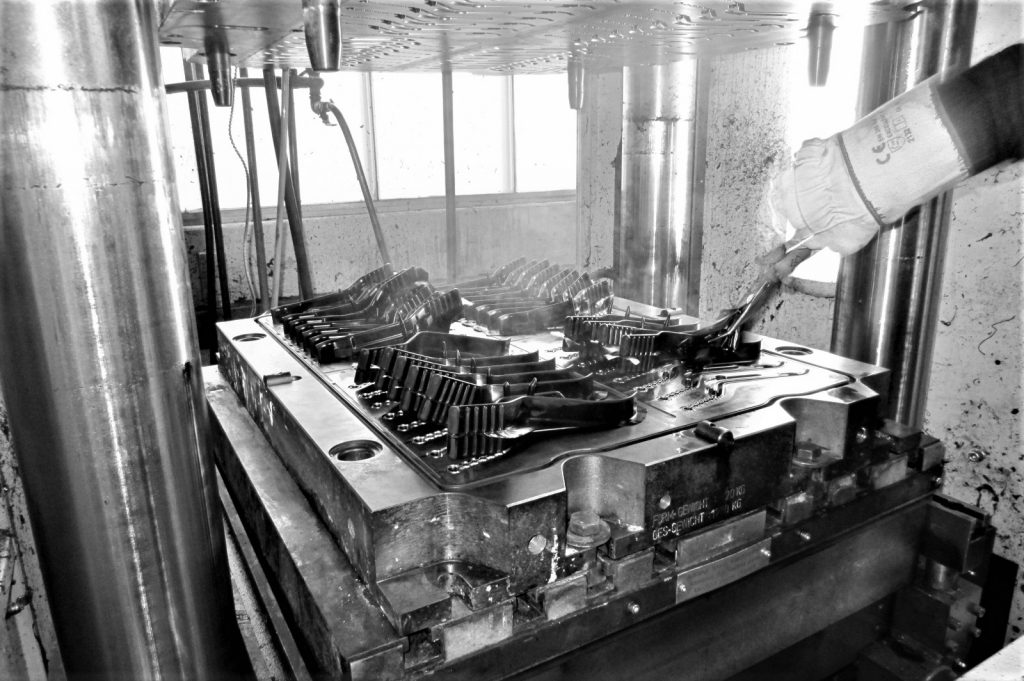

Demoulding

Many years of experience and know-how characterize our production employees, who are responsible for demolding and subsequent processing of the molded rubber parts according to very specific process technologies, specifications and quality goals.

Production quantities

We manufacture technical molded rubber parts for you from less than 100 up to millions of pieces at top conditions and exclusively at the production site in Germany.

Raw material suppliers

Since many years we cooperate with very experienced and 95 percent in Germany positioned elastomer manufacturers (for example, Phoenix Compounding) and can rely on their many years of expertise and wide-ranging knowledge by “Made in Germany” to 100 percent.

Flexibility

In the context of our very diversified and modern machine park, with a total of 23 injection molding presses of the brand MAPLAN and REP, we are able to highly complex and a wide variety of molded rubber part geometry, to realize new short-term orders as quickly as possible, as well as greatly increasing call volumes at any time to implement.

Quality

The production of the molded rubber parts is subject to a shift-accompanying SPC-managed production control (qualitative and quantitative test processes) based on DIN EN ISO, which is managed by the CAQ system.

Qtyahl

Machine

6

6

6

7

2

2

Press weight

Tons

160

160

250

250 XL

400

460

Clamping size

Tool

500 x 450 mm

500 x 450 mm

630 x 500 mm

650 x 560 mm

780 x 670 mm

800 x 710 mm

Max stroke

Tool

540 mm

540 mm

700 mm

700 mm

750 mm

830 mm